Unveiling the Birth of a Perfect Correction Tape

Time of publication:

2025-06-18

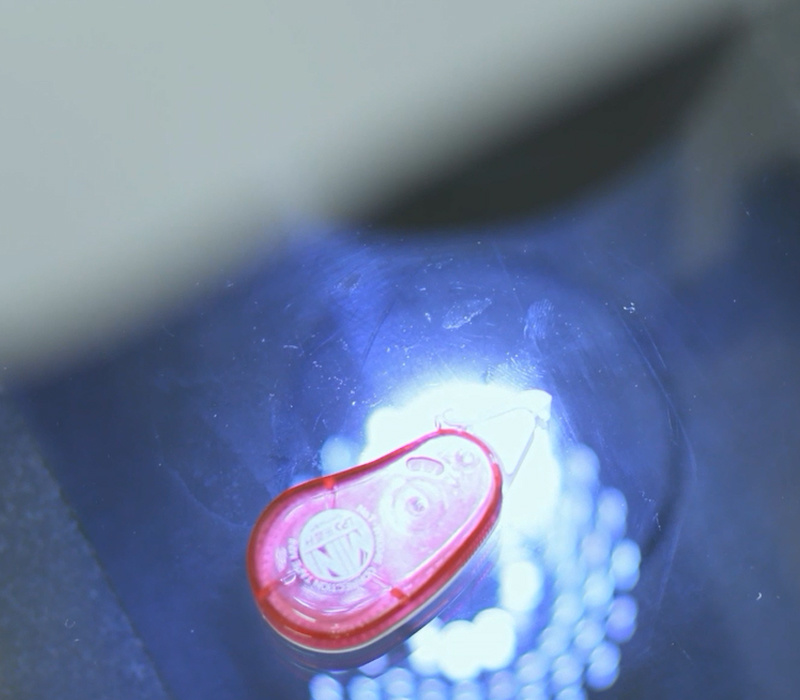

Think correction tapes are just rolled up casually? From raw materials to finished products, each tape undergoes rigorous testing akin to a "passport clearance"! Today, we’re stepping into the quality control lab to see how inspectors use "microscope-level standards" to safeguard your writing experience!

Intro: The "Invisible Battlefield" Behind Every Correction Tape

Think correction tapes are just rolled up casually? From raw materials to finished products, each tape undergoes rigorous testing akin to a "passport clearance"! Today, we’re stepping into the quality control lab to see how inspectors use "microscope-level standards" to safeguard your writing experience!

Phase 1: Raw Material

Tape Core Inspection: a surface smoothness rivaling an ice rink!

Shell Scrutiny: ABS material drop-tested from 3 meters—no cracks allowed. Gear mesh accuracy tolerance ≤0.05°.

Eco-Friendly Check: VOC (Volatile Organic Compounds) testing ensures fresh, non-toxic air.

Phase 2: Production

- Assembly Monitoring:

- Tape core tension test: 50 consecutive pulls without jamming.

2. Dynamic Simulation: - Mimics student writing pressure—pressure sensors detect if the cover layer breaks.

Phase 3: Finished Product

Durability Trial:

50 meters of continuous correction without breakage; gear lifespan ≥3,000 cycles.

Abuse Test:

- 1.5-meter free fall (5 times)—no dents, fully functional.

- Tape core twist test: 360° rotation still allows smooth dispensing.

Phase 4: Packaging

Label Audit: Production date, eco-certifications, safety marks—nothing missing!

Seal Check: Heat-shrink film tightness ≥95%—dust and moisture-proof.

Transport Simulation: Vibration table mimics 300km of jostling—ensures it arrives pristine.

Fun Fact: Our rejection rate is 12%—3x stricter than industry standards!

Consumer Tips: How to Spot Quality Tapes

- Shake Test: No rattling parts inside.

- Smooth Dispensing: No jams, no breaks.

- Uniform Coverage: Hold against light—no base color shows.

#StationeryQC #CorrectionTapeGuide #QualityMatters

Related News

Guangdong Lepusheng Stationery Co., Ltd

Tel: 86-754-83616505

Fax: 86-754-83846556

E-mail: gsj@lepusheng.com

Add: Wenguang Taoyuan Industrial Area,Chaoyang District,Shantou city,Guangdong,China

City,Guangdong,China(515100)

Mobile phone

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.